Data Drives Bioscience

Every project or effort in bioscience has associated data. There are also a plethora of tools available to deal with it. But it can be frustrating manually shoe-horning your data into containers that don’t match what you do — with no easy interface to retrieve what you need quickly. Sometimes the most valuable data are those you aren’t collecting.

BME Systems can analyze your workflow to determine commonalities, so that data can be kept, parsed and cleaned in a form that makes it available to everyone in the laboratory… for years. We’ll help you determine the right software stack that makes sense for all the parameters like durability, interface and cost.

Data can range from freezer sample storage information to -omic datasets that need to be parsed and cleaned for AI training.

We create both local and web-based applications using Python, Visual Basic, C++ and C as well as many instrument-specific languages. This includes databases commonly used in bioscience deployable locally or on cloud based systems like Google or AWS.

Software and Database Projects

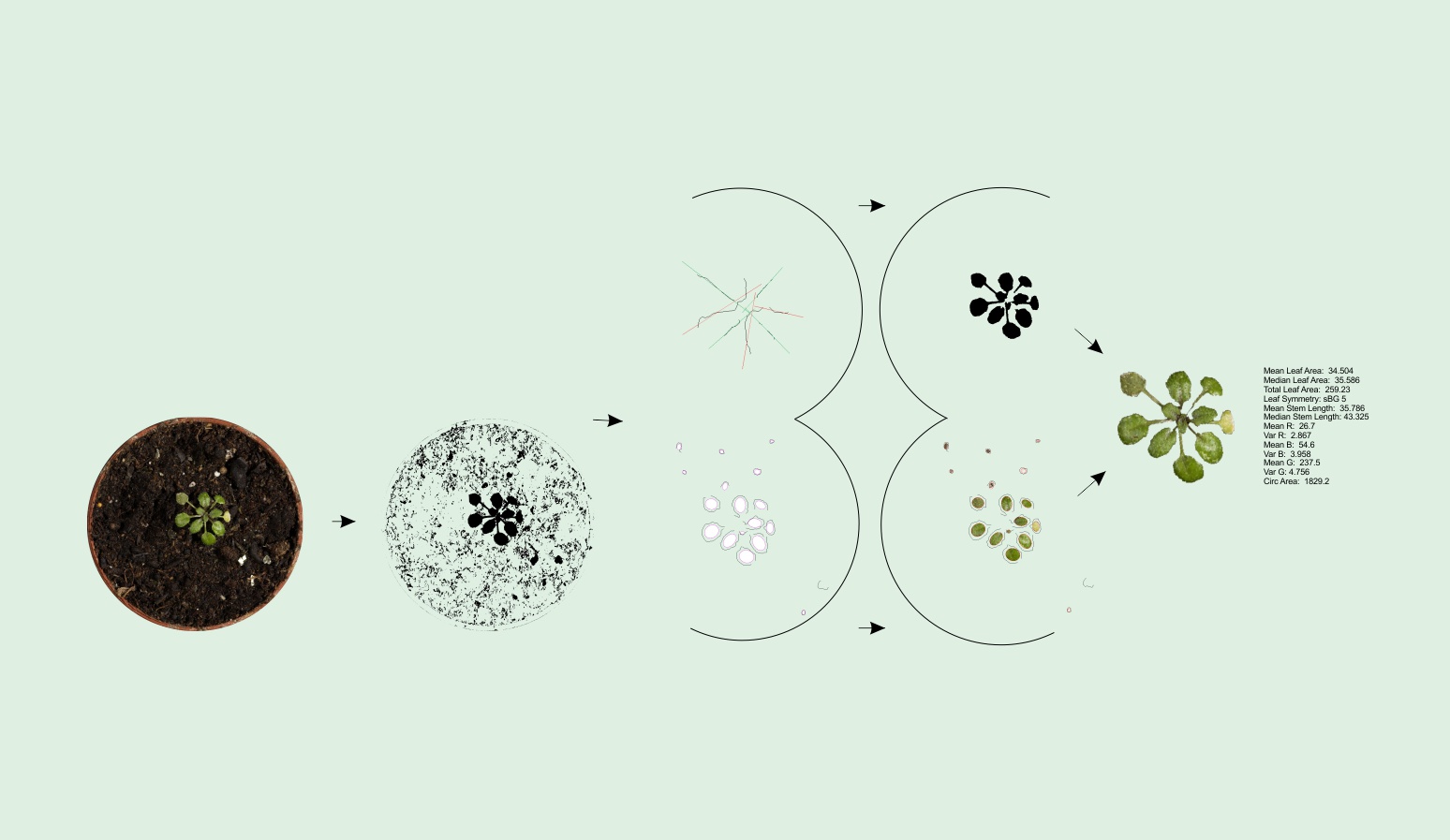

Analytical Software

Software that automatically extracts features from experimental data can save time and be a powerful enabler for discovery.

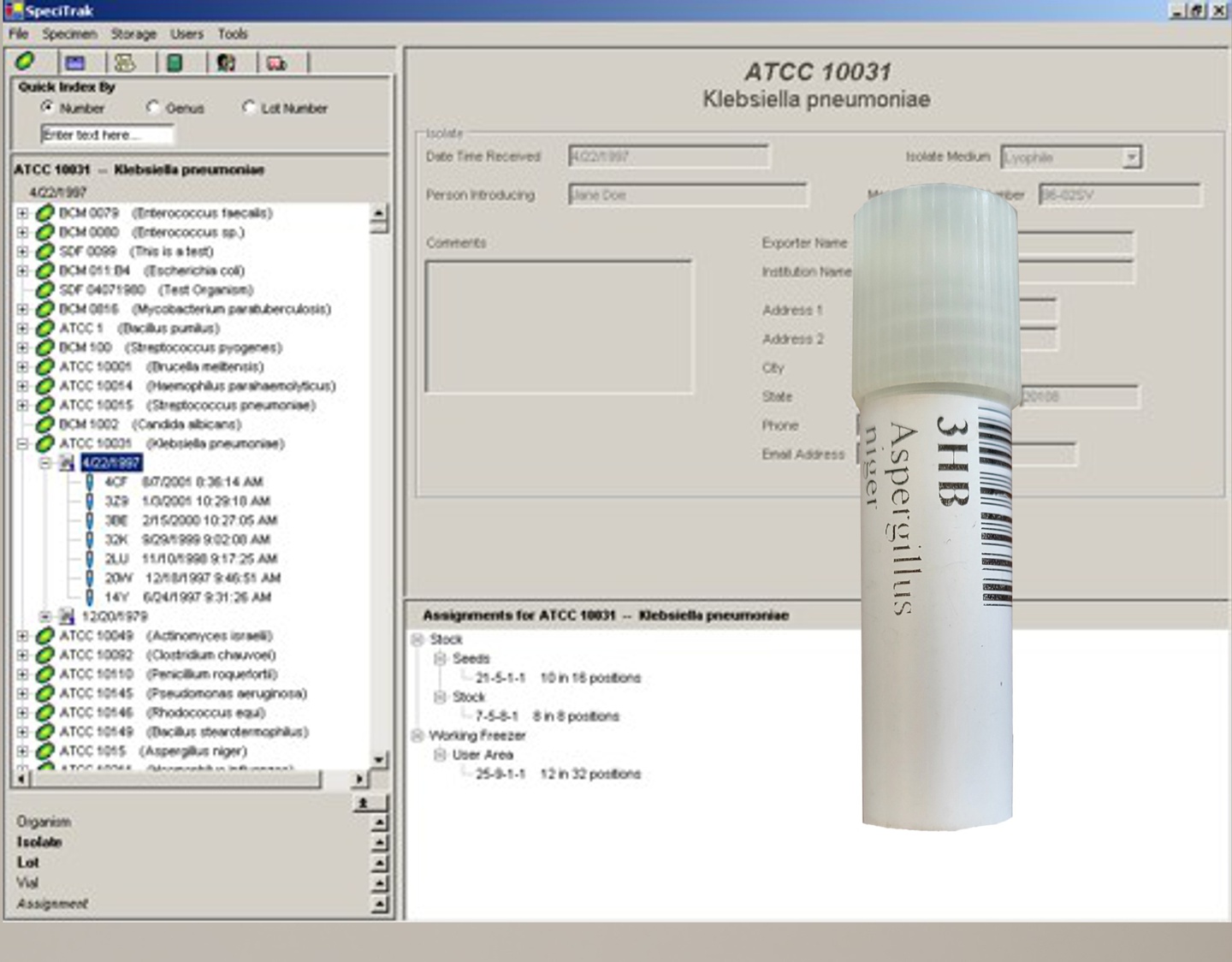

Culture Collection Management System

This system is organized by strain and tracks isolates and subculture lots in freezers for single and multi-site companies that produce cultures for internal use.

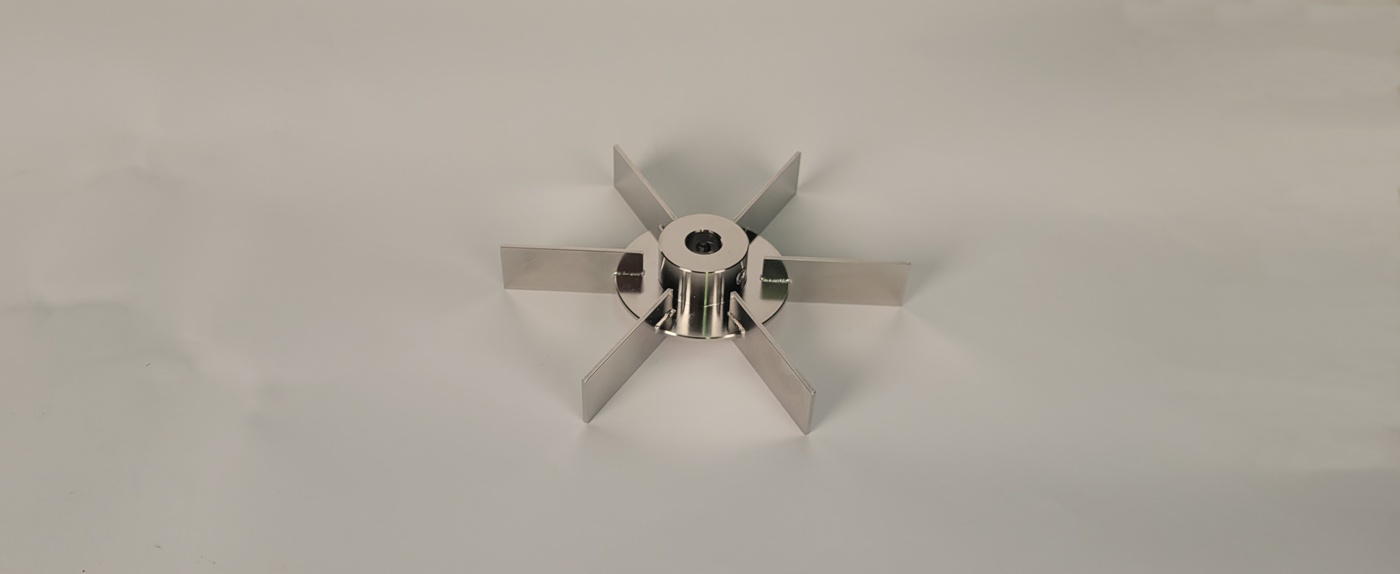

Industrial SCADA for Bioscience

Collecting data from over 3000 places to provide a comprehensive picture of 40 fermentations operating 24/7/365.